Sustainability is a very popular and important term these days. In broader sense it means merging the economic development with environmental concerns, leading to limit the use of resources such as habitats, raw materials, energy or human labour, as well as reduce hazardous, human-made effects.

Sustainability is a very popular and important term these days. In broader sense it means merging the economic development with environmental concerns, leading to limit the use of resources such as habitats, raw materials, energy or human labour, as well as reduce hazardous, human-made effects.

However, what exactly does it mean for passenger and cargo aviation? Answers can be found in one of the latest press releases issued by Boeing that includes more details on the company activities leading to sustainable and efficient operations.

In May of 2024, within ecoDemonstrator programme, the Boeing company began testing three dozen new technologies. Those tests are being performed with use of a special aircraft, created on basis of a Boeing 777-200 ER (Extended Range) airliner.

The aircraft made its first flight in 2012 and, since then, had tested 250 technologies. This year, the aeroplane will be used to examine various cabin interiors as part of programme aimed to reduce fuel consumption and crew workload, as well as to achieve higher reuse or recycle rate of the aircraft itself. At the end of May, four of the cabin technologies will be featured at the 2024 Aircraft Interiors Expo in Hamburg, Germany.

Since its initial flights in 2012, almost every platform of the Boeing ecoDemonstrator programme has flown on sustainable aviation fuel (SAF), and this year, the flagship aeroplane will fly on a 30/70 blend of SAF and conventional jet fuel.

´The Boeing ecoDemonstrator programme helps us make tangible improvements to our products – allowing us to reduce the environmental impacts of flying, improve the in-flight experience and strengthen the safety of our aeroplanes,´ said Stephanie Pope, president and CEO of Boeing Commercial Airplanes. ´We’re grateful for the many partnerships within aviation and beyond who help us turn the seemingly impossible into reality.´

In particular, the Boeing ecoDemonstrator projects include:

- Airport operations: Testing to enable single-engine taxi and digital taxi clearances to reduce fuel use and enhance safety by reducing pilot workload

- Airport noise: Quantifying the benefits of flight operation procedures, like steeper glide slope and continuous descent approach, to reduce community noise, fuel use and emissions

- Waste-reducing materials: Lighter, recyclable and more durable floor coverings and recycled carbon fibre ceiling panels – both made with 25% bio-based resin

- Noise and weight reduction: Cabin insulation to better reduce noise and regulate humidity and temperature, and fabric-covered acoustic panels for the bulkhead and galley

- Future cabin concepts: Economy and business class seats with sensors that detect if someone is seated during taxi, take-off and landing which can improve safety, and reduce crew workload and downtime for maintenance; a touchless water conservation lavatory; and galley technologies to make cabin service more efficient and reduce food waste

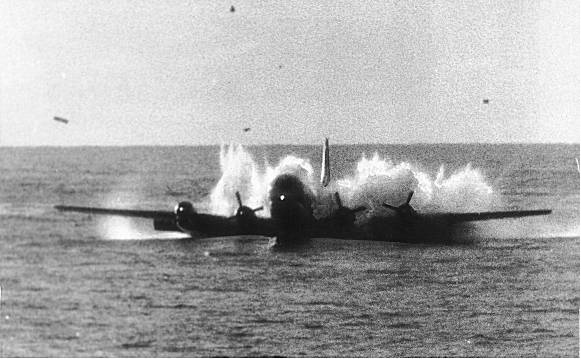

Cover photo: The Boeing ecoDemonstrator will test 36 technologies in the third year of testing on a 777-200ER (Extended Range), photo: © Boeing